CANDLE FILTER

Separation of liquid from solids takes place in chambers of filter press designed by Hidroforce™. After being locked within rigid chamber frames with expandable cloth membranes a sugar beet slurry gets gradually pressed to release liquid masses. Press filtering process is automatic and allows for adjustment of process parameters while well-positioned hydraulics reduces operation cycles.

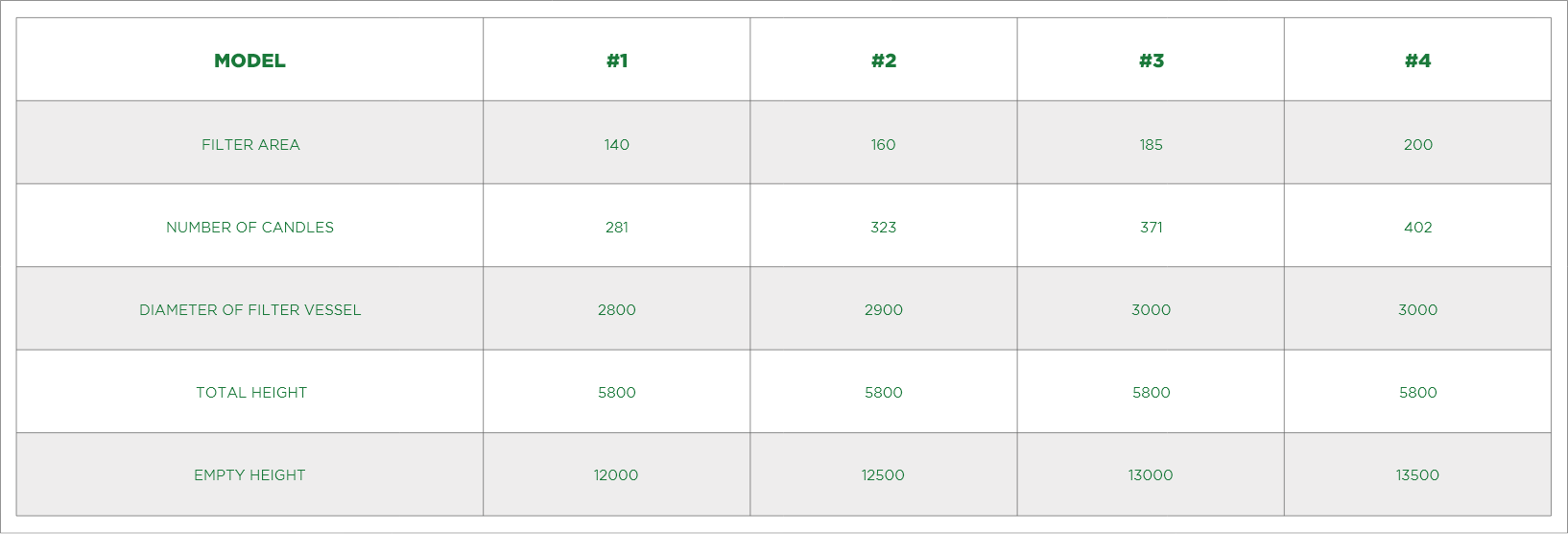

| Model | #1 | #2 | #3 | #4 |

| Filter area | 140 | 160 | 185 | 200 |

| Number of candles | 281 | 323 | 371 | 402 |

| Diameter of filter vessel | 2800 | 2900 | 3000 | 3100 |

| Total height | 5800 | 5800 | 5800 | 5800 |

| Empty weight | 12000 | 12500 | 13000 | 13500 |

| Max operating pressure | 6-8 bar | 6-8 bar | 6-8 bar | 6-8 bar |

| Vessel materials | St37-2 | St37-2 | St37-2 | St37-2 |

| Each Candle | ||||

| Diameter | 60 | 60 | 60 | 60 |

| Length | 2500 | 2500 | 2500 | 2500 |

| Material | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

| Cycle Time | ||||

| 1st carbonation | 20-40 min | 20-40 min | 20-40 min | 20-40 min |

| 2nd Carbonation | 90-120 min | 90-120 min | 90-120 min | 90-120 min |